Stainless Steel Flanges Manufacturer in India

Stainless Steel RTJ Flanges Dealer, ASTM A182 SS Pipe Flanges Exporter, Stainless Steel 321 Flanges Manufacturer in India

Sri Keshariya Metal is a top-quality Stainless Steel Flanges Manufacturer in India. We supply our SS Plate Flanges with secure sealing in piping systems and are easy to install. Our Stainless Steel RTJF Flanges Supplier range features raised faces for better gasket compression in high-pressure joints. We also stock ANSI B16.5 Stainless Steel Pipe Flange options, ensuring compatibility and durability across various industrial operations—all at competitive prices.

Other Types of Stainless Steel Flanges

-

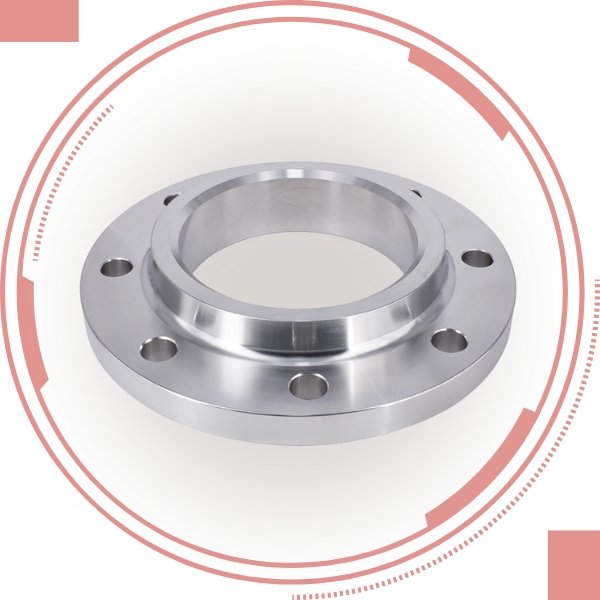

ANSI B16.5 Weld Neck SS Flanges

-

SS Flat Welding Flange

-

316TI Stainless Steel Pipe Flange

-

SS Forged Flanges

-

ASTM A182 SS Plate Flanges

-

SS Blind Flanges

-

ASTM A182 SS Socket weld Flanges

-

ANSI B16.5 SS Blind Flanges

Stainless Steel RTJ Flange Exporter, ASME B16.47 Nipo Flange Supplier, Stainless Steel Slip-on Flange Supplier in India

Sri Keshariya Metal is a notable Stainless Steel Flanges supplier in India. Our Stainless Steel Socket Welding Flange is also designed to make tight high-strength joints in which an internal weld is necessary. The SS Long Weld Neck Flanges are manufactured to incorporate a long hub, which offers great reinforcement of high-pressure pipelines. We also supply SS Slip-on Flanges, which are manufactured with welding quite easy and are suitable for areas of low pressure where rapid fabrication is highly required. We are also a top Stainless Steel Round Bar manufacturer in India.

Specifications of Stainless Steel Flanges

| Specifications | ASTM A182 Stainless Steel Flanges |

| Types Of SS Flanges | Blind/ Slip On/ Weld Neck/ Socket Weld/ RTJ/ Lap Joint/ Threaded/ Reducing Flanges |

| SS Flange Dimensions | EN 1092-1/ EN 1092-2/ DIN 2501/ DIN 2527 |

| Size | 1" (12 NB) to 48" (1000NB) DN10~DN5000 |

| Face Type | Ring Type Joint (RTJ)/ Raised Face/ Flat Face |

| Available Grades | ASTM A182 F304 & F304L/ ASTM A182 F316 & F316L/ ASTM A182. |

| Flange Forging Methods | Forging/ Casting/ Rolling And Cutting |

| Pressure Rating | Class 150/ Class 300/ Class 400/ Class 600/ Class 600/ Class 900/ Class 1500/ Class 2500. |

| Pressure Calculation in DIN | PN6, PN10, PN25, PN40, PN64 | 6Bar, 10Bar, 16Bar, 25Bar, 40Bar. |

Types of Stainless Steel Flanges

Contact us Now!!

Stainless Steel Flanges Chemical Properties

| Type | Carbon | Manganese | Phosphorus | Sulphur | Silicon | Chromium | Nickel | Molybdenum |

| 302 | 0.15 | 2.00 | 0.045 | 0.030 | 1.00 | 17.00/19.00 | 8.00/10.00 | – |

| 309 | 0.20 | 2.00 | 0.045 | 0.030 | 1.00 | 22.00/24.00 | 12.00/15.00 | – |

| 304L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/12.00 | – |

| 304* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/10.50 | – |

| 309S | 0.08 | 2.00 | 0.045 | – | 1.00 | 22.00/24.00 | – | – |

| 317 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00/1.00 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316* | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 310 | 0.25 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316L* | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 347 | 0.08 | 2.00 | 0.040 | 0.030 | 0.5/1.00 | 17.00/19.00 | 9.00/12.00 | 0.5/0.75 |

| 317L | 0.03 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 321 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 17.00/19.00 | 9.00/12.00 | 0.75/0.75 |

Stainless Steel Flanges Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Heat Treating Temperature, min or range (°C) |

| 304/304H | 515 min | 205 min | 28% | 1040 |

| 304L | 485 min | 170 min | 28% | 1040 |

| 310/310S | 515 min | 205 min | 28% | 1040 |

| 316/316H | 515 min | 205 min | 28% | 1040 |

| 316L | 485 min | 170 min | 28% | 1040 |

| 316Ti | 515 min | 205 min | 28% | 1040 |

| 317/317L | 515 min | 205 min | 28% | 1040 |

| 321/321H | 515 min | 205 min | 28% | 1040-1050 |

Applications of Stainless Steel Flanges

The Standards We Follow while manufacturing our SS Flanges:

Packaging of Stainless Steel Flanges

-

Gunny Bags / Woven Sacks

-

Cartons Boxes

-

Wooden Boxes

-

Plastic-Wrapped Packaging

-

Custom Packaging

-

Box Packaging